Wire Manufacturing Parameters

From our manufacturing facility Garnett Wire supplies a comprehensive range of metallic card clothing.

- High grade carbon steel

- Precision rolled section

- Hardened and tempered for secure mounting and durability

- Cut to point precision tooth

- Aluminium and plastic interlocking base wires

- Bespoke specifications

- Stainless steel and variable pitch available

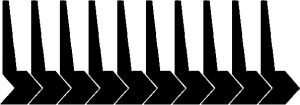

Interlocking Wire

- Available from 4 to 28 rows per inch

- Interlocking features ensure wire remains on the roller even after breakage has occurred - prevents costly damage and loss of card clothing on adjacent rollers.

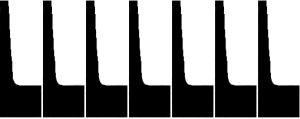

Surface Wound Wire

- Available from 8 to 42 rows per inch

- Higher row specifications produce concentrated point densities - ideal where load on the wire does not require interlock system.

- Lightweight non-wovens, worsted cylinder and a full range of different wires.

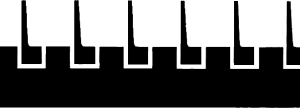

In-Groove Wire

- Available from 2 to 13 rows per inch.

- Precisely engineered to ensure tight friction fit withstand working pressures on tooth.

- Particularly used on feed rollers and multi starts.

Morel

Non-woven Cylinder/Worker

High Production Doffer

Woolen / Worsted

Blow Room

Random Pitch

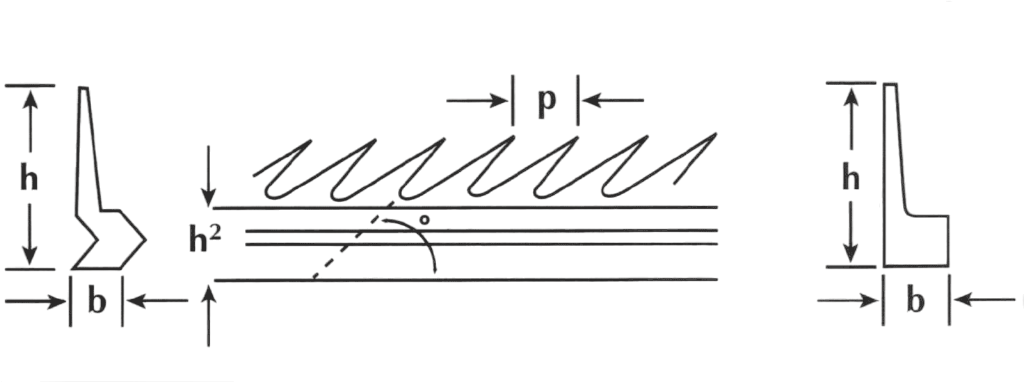

Garnett Interlocking Wires h² = 2.2mm

| Wire Ref | Base b (mm) |

Height h (mm) |

Pitch p(mm) |

Front Angle° |

PPSI | Feed / Lickerin |

Transfer | Cylinder | Workers | Strippers | Doffer |

| V6/360 | 4.25 | 7.5 | 8.5 | 60° | 18 | • | • | • | • | • | |

| V6/365 | 4.25 | 6.0 | 8.5 | 65° | 18 | • | • | • | • | • | |

| V8/3553 | 3.2 | 7.5 | 7.3 | 53° | 28 | • | • | • | |||

| V8/460 | 3.2 | 6.0 | 6.3 | 60° | 32 | • | • | • | • | ||

| V8/4570 | 3.2 | 6.0 | 5.5 | 70° | 36 | • | • | • | |||

| V10/3670 | 2.5 | 6.0 | 7.0 | 70° | 36 | • | • | • | |||

| V10/553 | 2.5 | 5.25 | 5.0 | 53° | 50 | • | • | • | • | • | |

| V10/560 | 2.5 | 5.5 | 5.0 | 60° | 50 | • | • | • | • | ||

| V10/480 | 2.5 | 6.0 | 6.3 | 80° | 40 | • | • | ||||

| V12/565 | 2.1 | 5.0 | 5.0 | 65° | 60 | • | • | • | • | ||

| V12/575 | 2.1 | 5.0 | 5.0 | 75° | 60 | • | • | ||||

| V14/670 | 1.8 | 5.0 | 4.2 | 70° | 84 | • | • | ||||

| V14/550H | 1.8 | 6.5 | 5.0 | 50° | 70 | • | • | ||||

| V16/553 | 1.6 | 5.0 | 5.0 | 53° | 80 | • | • | • | • | ||

| V16/5585 | 1.6 | 5.0 | 4.6 | 85° | 88 | • | • | ||||

| V18/6350H | 1.4 | 6.0 | 4.0 | 50° | 113 | • | • | ||||

| V20/560 | 1.3 | 5.0 | 5.0 | 60° | 100 | • | • | • | |||

| V20/775 | 1.3 | 5.0 | 3.6 | 75° | 140 | • | • |

Interlocking Wires h² = 1.5mm

| Wire Ref | Base b (mm) |

Height h (mm) |

Pitch p(mm) |

Front Angle° |

PPSI | Feed / Lickerin |

Transfer | Cylinder | Workers | Strippers | Doffer |

| V8/365 | 3.2 | 5.0 | 8.5 | 65° | 24 | • | • | • | • | • | |

| V12/570 | 2.1 | 4.5 | 5.0 | 70° | 60 | • | • | ||||

| V16/675 | 1.6 | 4.5 | 4.2 | 75° | 96 | • | • | ||||

| V16/760 | 1.6 | 4.5 | 3.6 | 60° | 112 | • | • | • | |||

| V20/6350H | 1.3 | 5.5 | 4.0 | 50° | 126 | • | • | ||||

| V20/8570 | 1.3 | 4.0 | 3.0 | 70° | 170 | • | • | ||||

| V24/665 | 1.1 | 4.5 | 4.2 | 65° | 144 | • | • | • | |||

| V24/1070 | 1.1 | 4.0 | 2.5 | 70° | 240 | • | • | ||||

| V24/6350H | 1.1 | 5.5 | 4.0 | 50° | 151 | • | • | ||||

| V28/880 | 0.9 | 3.5 | 3.2 | 80° | 224 | • | |||||

| V28/955 | 0.9 | 4.5 | 2.8 | 55° | 252 | • | • |

Section Wires, Surface or Groove Mounted

| Wire Ref | Base b (mm) |

Height h (mm) |

Pitch p(mm) |

Front Angle° |

PPSI | Feed / Lickerin |

Transfer | Cylinder | Workers | Strippers | Doffer |

| G97/2560 | 2.46 | 9.0 | 10.0 | 60° | • | ||||||

| G88/2265 | 2.2 | 9.0 | 11.5 | 65° | |||||||

| G63/365 | 1.6 | 6.0 | 8.5 | 65° | • | • | |||||

| G525/553 | 1.3 | 4.3 | 5.0 | 53° | • | • | • | • | |||

| G36/870 | 0.9 | 3.2 | 3.2 | 70° | 224 | • | • | ||||

| G36/1050 | 0.9 | 3.2 | 2.5 | 50° | 280 | • | • | ||||

| G36/1480 | 0.9 | 3.2 | 1.8 | 80° | 392 | • |